Efficiency

A new era of fleet productivity: Expanded Maintenance and integrated DVIRs

September 30, 2025

Vice President, Product Marketing

For today's fleets, the reality of maintenance operations can be messy. Mechanics can waste valuable time doing paperwork instead of repairs, drivers submit incomplete inspection reports, and managers lack visibility into how maintenance dollars are being spent. The result? Delayed repairs, inaccurate data, and vehicles out of service longer than necessary. Problems like these inevitably add up to higher costs, lower productivity, and customer dissatisfaction.

Samsara Maintenance, the only Computerized Maintenance Management System (CMMS) built on Samsara Intelligence, provides a consolidated view of critical maintenance information to save time, improve asset utilization, and track costs. Maintenance uses AI to accelerate work order creation, reduce repeat shop visits, analyze cost trends, and streamline workflows by integrating maintenance directly into the existing Samsara ecosystem.

And we're not stopping there. To build on this powerful foundation, we're excited to announce new enhancements to Samsara's integrated platform—DVIRs powered by AI, and expanded fleet maintenance solutions built to connect your operations and keep your assets on the road.

New maintenance features to keep your assets working

Our maintenance platform comes with new, expanded features that give you a complete, unified view of your assets, including DVIRs, work orders, and parts inventory. These features include:

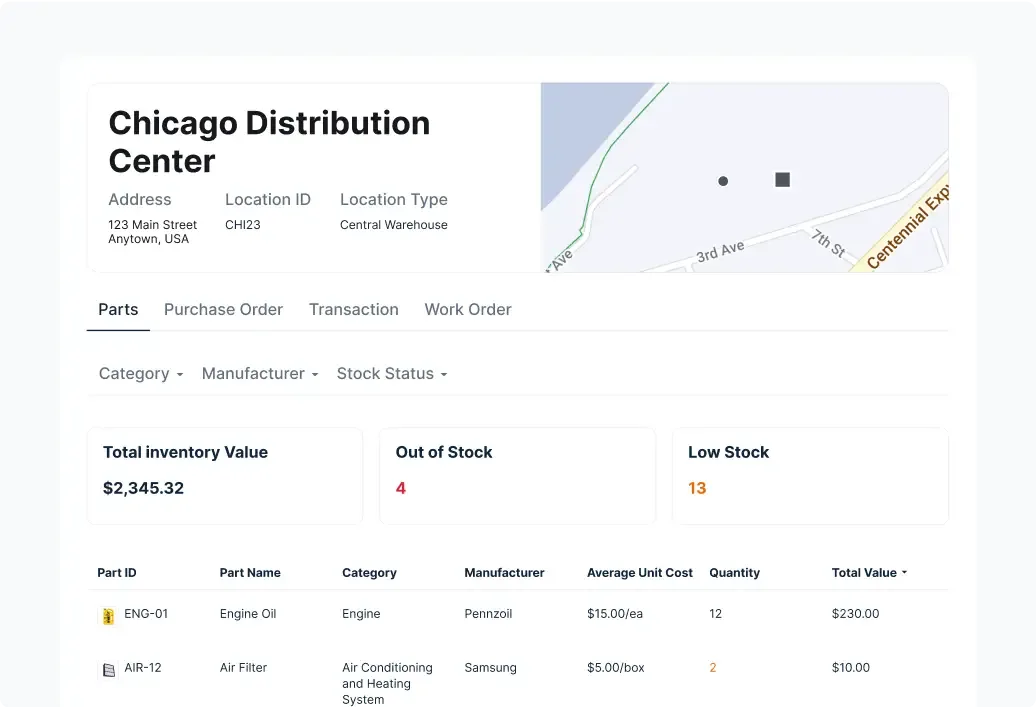

Inventory management: Set up locations and track the quantities, consumption, and availability of parts. Get low-stock and out-of-stock notifications so you can replenish parts proactively, avoiding idle time and ensuring your team has what it needs before a maintenance job even starts. This comprehensive part tracking system helps you understand where maintenance dollars are being spent and streamline accounting transactions.

Prevent the use of unsafe vehicles: If a vehicle has an unsafe DVIR, you can mark it as “out of service” to prevent drivers from taking it out. This mitigates the risk of costly on-road breakdowns, high-cost third-party repairs, and safety hazards.

Overall, these expanded features mean more wrench time for your mechanics and more uptime for your fleet. They can:

Provide visibility into maintenance spending: Easily track and understand where your maintenance budget is going with tools that provide enhanced financial insights.

Improve mechanic efficiency: Cut down on non-wrench time by streamlining workflows with an all-in-one system.

Increase asset utilization: Reduce the time assets spend in the shop by shortening repair times and proactively managing parts and repairs.

“Faster asset management means less downtime and more convenience for the crews. It also saves time for us to un-tool and re-tool trucks, which is a huge cost savings. And for our customers, it means more uptime.”

Autumn Miller, Support Specialist, Utility Supply and Construction Company

Improve compliance with faster, more accurate DVIRs powered by AI

Drivers need to complete DVIRs quickly and accurately, but the process can often be slow and frustrating. Our advanced DVIR features use AI to make inspections faster and more accurate for drivers while providing managers with higher-quality data.

Samsara’s new DVIR features include:

AI quality checks: Our AI helps verify the accuracy of DVIR submissions. The solution can detect if a driver is too far from a vehicle during an inspection or confirm that a required photo is actually of a vehicle component and not an irrelevant image, helping you catch and prevent inaccurate reports.

Voice transcriptions for notes: Drivers can simply speak as they see an issue—“front right headlight is out,” for example—and the solution transcribes them. This feature eliminates the need for drivers to type in cold weather or with gloves on, making it easier and faster to submit detailed notes and resulting in more complete and higher-quality DVIRs.

Seamless work order creation: With a single click, you can automatically create a work order directly from a DVIR defect. The solution populates key details and even suggests additional items, saving time and eliminating transcription errors.

Automatic DVIR resolution: When a work order is marked as complete within Samsara, the corresponding DVIR defect is automatically resolved, ensuring a full record from inspection to repair and creating a seamless, closed loop.

“We are multiple companies serving multiple industries with different equipment, so we didn’t create a lot of generalized templates or forms before. With AI DVIR, we can customize the form with a photo of the defect and quickly identify what is wrong.”

Autumn Miller, Support Specialist, Utility Supply and Construction Company

Taking fleet maintenance and efficiency to the next level

By connecting maintenance and DVIR workflows with a single, integrated platform, these new solutions help your team work more efficiently, minimize labor costs, and get your fleet back on the road faster. This means more revenue, better asset utilization, and a more transparent view of your maintenance operations.

Attend our webinar to learn more and see a live demonstration of these new features. Register here.